- Products

- Catalogs

- News & Trends

- Exhibitions

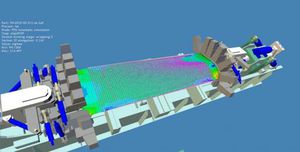

Electric press FSP60formingfor the aerospace industryCNC

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Operation

- electric

- Function

- forming

- Other characteristics

- for the aerospace industry, CNC

- Pressing force

Max.: 12,500 tf

Min.: 60 tf

Description

Metallic or ceramic platens

Platen sizes, strokes, daylights on demand

High thermal efficiency

- Multiple zone heating up to 1920°F

- High efficiency insulation

- Heater failure detection

- Optional door heaters

- Low impact on environment

- Tool temperature regulation

High precision and repeatability of forming cycle.

- High precision gas control with several independently controlled lines

- High precision servo controls

- Full traceability of all forming and press parameters

- Optimal gas pressure control

Many available options:

- Gas purity monitoring

- Lower platen shuttle

- Die lifting pins

- Diffusion bonding

- Hot forming capability

Typical parts produced on this type of machine are: Titanium, Aluminum, and Nickel based alloy parts, pylon panels, nacelle panels, firewalls, engine parts, fan and OGV

Standard superplastic forming machines:

The table here under is an indication to give you an overview of the machines we already installed. Each machine can be customized according to your requirements.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.