- Products

- Dantec Dynamics

Digital correlator with CMOS camera FlexDIC3D correlation

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Other characteristics

- with CMOS camera, 3D correlation

- Spatial resolution

94 µm, 122 µm, 204 µm

- Cameras number

1 unit, 2 unit, 3 unit

Description

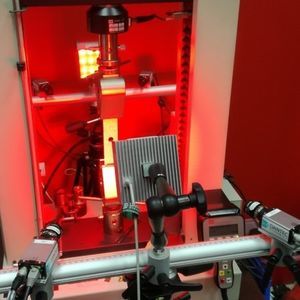

The FlexDIC is a Digital Image Correlation (DIC) measurement system designed as a flexible, robust and multi-functional industrial & academic utility for a wide range of materials testing & motion analysis applications.

This easy-to-use system can perform all your testing needs allowing any user to quickly perform accurate & precise measurements for displacement, contour (shape), strain, and (discrete) kinematic quantities of tracked points. The FlexDIC is completely modular and can be upgraded with additional lenses, calibration targets, illumination systems, and also with additional cameras turning the system into a MulticamDIC system.

The FlexDIC is a complete & fully equipped system, supplied (as standard) with one Laptop PC, one DAQ Controller, lenses, calibration targets, mounting, and a tripod. The measurement performance is harnessed using either; 1x, 2x, or 3x CMOS cameras with USB3 or GiGE vision technology. (A standard FlexDIC system consists of a 3-camera system).

The system can be operated in either; DAQ Triggered or Master/Slave mode. Using the DAQ Controller, the FlexDIC can read in up to 8x +/-10V analogue signals (i.e. for a load cell or LVDT). It also allows up to 2 analogue outputs to be read-out from Istra4D (requiring the DSM 32015: Istra4D Real-Time Correlation Evaluation Module).

This easy-to-use system can perform all your testing needs allowing any user to quickly perform accurate & precise measurements for displacement, contour (shape), strain, and (discrete) kinematic quantities of tracked points.

Possible material testing & motion analysis applications include; simple, quasi-static tension, compression, buckling

VIDEO

Catalogs

No catalogs are available for this product.

See all of Dantec Dynamics ‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.