- Production - Materials - Metrology

- Surface treatment

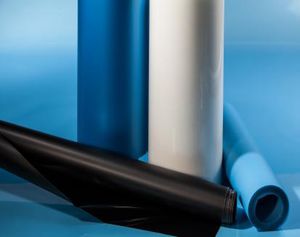

- Protective coating

- SAINT-GOBAIN PERFORMANCE PLASTICS - SPECIALTY FILMS

Insulation coating 4000protectivefor the aerospace industryanti-static

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- protective, insulation

- Applications

- for the aerospace industry

- Other characteristics

- anti-static

Description

NORFILM is the industry leader for customizable adhesive release liners that are used in a broad range of applications. Our formulations are custom made to meet the specific demands for non-stick feel, adhesive chemistry and storage and use requirements. NORFILM custom coatings and solutions can provide the perfect solution for release liner applications.

The NORFILM release series 4000, 7000, and 8000 are all based on ultraviolet (UV) cured silicone. These coatings are designed for easy and controlled release on multiple substrates. They exhibit good adhesion to base films, excellent solvent resistance, and good winding characteristics. These coatings are sold into numerous markets and end applications including medical, electronics and industrial.

BENEFITS:

FDA compliant formulas suitable for food contact

Compatible with most adhesives

Easy release: controlled release formulations, differential release constructions

Allows for double-sided release as a processing aids or finished products

Premium feel on finished products

Excellent abrasion and solvent resistance

Can be customized for each application

Catalogs

Other SAINT-GOBAIN PERFORMANCE PLASTICS - SPECIALTY FILMS products

NORFILM Performance Coated Solutions

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.