- Production - Materials - Metrology

- Materials - Semi-finished products

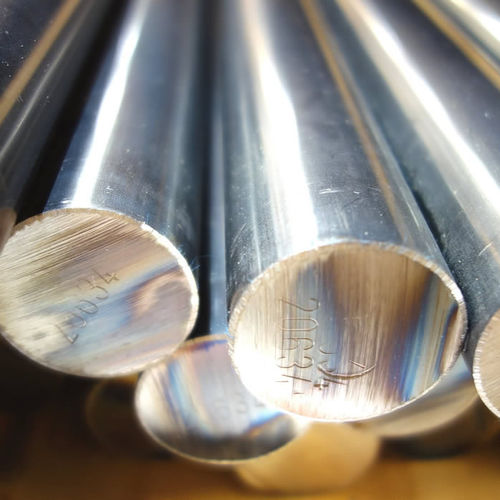

- Rod nickel

- SMITHS ADVANCED METALS

Rod nickel alloy 400 for the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Form

- rod

- Other characteristics

- for the aerospace industry

- Mechanical resistance

Max.: 600 MPa

Min.: 170 MPa

- Typical elongation

20 %, 35 %

Description

Alloy 400 offers superb corrosion resistance and is one of few alloys that may be used with hydrochloric and fluorine. Alloy 400 (often known by the branded name Monel®) retains its mechanical properties from cryogenic to high temperatures and displays excellent corrosion resistance up to 400°C. Corrosion resistance is particularly impressive in rapid flowing seawater or brackish water. Therefore, Alloy 400 (NA13) is highly suitable for offshore, marine, and chemical processing applications. The material is readily weldable and cold formable. The product offers immunity to chloride-induced stress corrosion cracking.

Stock Availability

We stock Alloy 400 bars in the cold drawn and hot worked conditions, available in various incremental sizes to suit your engineering requirements.

Benefits

Alloy 400 offers numerous performance benefits, including good strength and toughness, excellent corrosion resistance at low and high temperatures and immunity from chloride-induced stress corrosion cracking.

Grades / Specifications

2.46360

2.4361

BA13

NiCu30Fe

ASTM B164, ASME SB164

ASTM B564, ASME SB564

BS 3076

NACE MR 0103

NACE MR 0175

Applications

Chemical processing

Offshore applications

Propeller shafts

Marine fixtures

Product Benefits

Excellent corrosion resistance at both high and low temperatures

Good strength

Good toughness

Immune to chloride induced stress corrosion cracking

Catalogs

Alloy 400

1 Pages

Related Searches

- Aeronautical stainless steel

- Stainless steel

- Alloy steel

- Aeronautical alloy steel

- Titanium alloy

- Aeronautical titanium alloy

- Aluminum alloy

- Aeronautical aluminum alloy

- Steel alloy for the aerospace industry

- Stainless steel for the aerospace industry

- Aerospace titanium alloy

- Nickel alloy

- Nickel alloy for the aerospace industry

- Aluminum for the aerospace industry

- Titanium alloy rod

- Bronze

- Aeronautical copper alloy

- Rod nickel alloy

- Rod stainless steel

- Steel alloy rod

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.