- Production - Materials - Metrology

- Materials - Semi-finished products

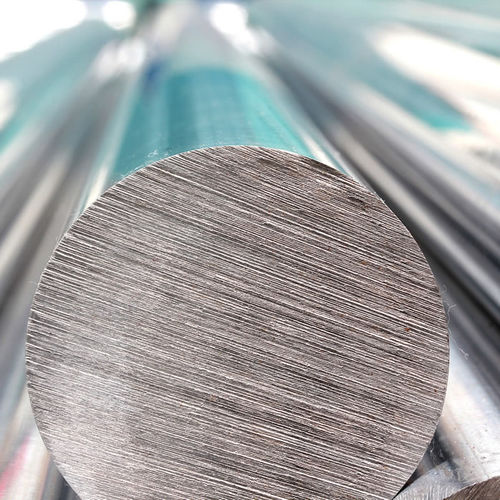

- Steel rod

- SMITHS ADVANCED METALS

Steel alloy rod 9310 for the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Form

- rod

- Other characteristics

- for the aerospace industry

- Mechanical resistance

861.8 MPa

Description

Alloy 9310 combines high fatigue strength with high core hardness. The low alloy product offers high hardenability and is particularly useful in high core strength applications, especially in aerospace. 9310 is a nickel-chromium-molybdenum alloy that offers good strength and toughness. The material is suitable for machining in the normalised, tempered state. The performance characteristics of the alloy improve further after annealing with better ductility and machinability. 9310 also promotes excellent transverse properties.

Commercial Applications

The product finds use in engineering applications such as aircraft and helicopter parts, clutches, heavy-duty gears and shafts.

About Carburising

Carburising is a type of heat treatment process performed on low carbon steels to enhance the alloy's strength, hardness, and wear characteristics. Treatment time and temperature dictate how much carbon is absorbed by the steel and how hard, strong and wear-resistant the resultant alloy will be.

Stock Availability

Smiths Advanced Metals stocks 9310 steel bars in the normalised and tempered condition and in closer incremental sizes to suit your particular engineering requirements.

Grades / Specifications

299-947-032

AMS6260

AMS6267

MIL-S-7393

Applications

Heavy-duty gears

Clutches

Helicopter parts

Shafts

Product Benefits

Excellent transverse properties

High hardenability

High fatigue strength

For high core strength applications

Catalogs

No catalogs are available for this product.

See all of SMITHS ADVANCED METALS‘s catalogsRelated Searches

- Aeronautical stainless steel

- Stainless steel

- Alloy steel

- Aeronautical alloy steel

- Titanium alloy

- Aeronautical titanium alloy

- Aluminum alloy

- Aeronautical aluminum alloy

- Steel alloy for the aerospace industry

- Stainless steel for the aerospace industry

- Aerospace titanium alloy

- Nickel alloy

- Nickel alloy for the aerospace industry

- Aluminum for the aerospace industry

- Titanium alloy rod

- Bronze

- Aeronautical copper alloy

- Rod nickel alloy

- Rod stainless steel

- Steel alloy rod

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.