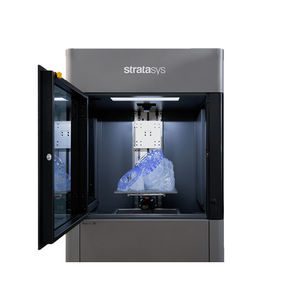

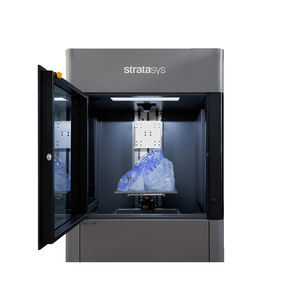

ABS 3D printer Neo450sFDMfor the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Printed material

- ABS

- Heating technology

- FDM

- Domain

- for the aerospace industry

- X travel

450 mm

(17.72 in)- Y travel

450 mm

(17.72 in)- Z travel

400 mm

(15.75 in)

Description

If you’re looking for higher throughput, the Neo800+ 3D printer can achieve up to 50% faster builds than with the Neo800 printer, thanks to ScanControl+.

ScanControl+ enhances border control, resulting in sharper corners, smoother edges, and finer details. It optimizes laser pathing to ensure faster, more efficient scanning, while intelligent energy delivery maintains part fidelity even at higher speeds.

Versatile SLA materials for every application

Designed with an open resin system, Neo printers such as the Neo450s, Neo800, and Neo800+ 3D printers are designed to run the most technically advanced SLA materials, including the Somos® resins range.

From clear, tough and durable resins to high-temp rigid options, the combination of Somos SLA resins and Neo 3D printers deliver superior accuracy, durability, and surface quality for prototypes and production parts. Somos resins are available for standard use to run on the Neo800 3D printer and Neo450s 3D printer. The Neo800+ 3D printer further expands capabilities by supporting both standard and ScanControl+ ready materials for faster build speeds.

SLA materials have advanced beyond general-purpose prototyping to high-performance options engineered for durability, heat resistance, and end-use part production. Achieve exceptional precision, durability, and quality in your 3D prints.

Learn more about the range of Somos stereolithography materials for the Neo 3D printer.

Explore how stereolithography 3D printing with the Neo 3D printer is empowering industries to build the future of manufacturing and design.

VIDEO

Catalogs

No catalogs are available for this product.

See all of STRATASYS GMBH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.