Field measuring instrument FlawExplorer surfacelaserfor the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Measured value

- surface, field

- Technology

- laser

- Applications

- for the aerospace industry

- Other characteristics

- automatic

Description

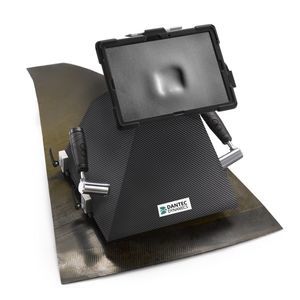

The FlawExplorer is a laser shearography NDT sensor designed to be used for post-production quality control applications or in-field (in-service) component inspections. Depending on the application, the sensor can be configured with thermal or vacuum (partial) excitation systems and may also be automated. It incorporates the very latest in phase-shifting technology delivering accurate and reliable measurement results through clear and sharp imaging with sub-micrometer displacement resolution.

The FlawExplorer sensor is completely contained in one, lightweight (5 kgs / 11 lbs) unit. Only two connections are required to operate the sensor; one for power and one for camera data. With fully integrated imaging & control electronics, the sensor incorporates; a (standard) 3.2 MPx or (optional) 5 MPx, CMOS camera with a maximum frame rate of 37 & 24 Hz, respectively, a varifocal zoom lens, eight (Class 3R) laser diodes, automatic shearing, automatic projection calibration, and phase-shifting piezos. The sensor is contained in an aluminum housing with a detachable safe-guard ring, the rugged design of the FlawExplorer is designed to withstand shocks, knocks, and vibrations.

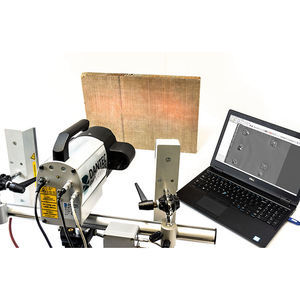

Laser Shearography has one of the highest inspection rates compared to any NDT method, specifically because it utilizes a large Field-of-View (FoV) from the use of multiple coherent laser diodes.

A FlawExplorer uses 8 laser diodes to generate a large illumination area = Field-of-View (FoV). For a standard 3.2 MPx camera, the achievable projected image size in one shot can be up to 2.9 m x 2.1 m (9.4 ft x 7.0 ft) or for an optional 5.0 MPx camera, up to 3.4 m x 2.8 m (11.2 ft x 9.3 ft)

VIDEO

Catalogs

No catalogs are available for this product.

See all of Dantec Dynamics ‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.