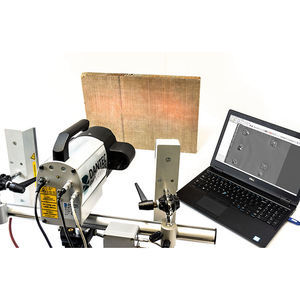

Field measuring instrument FlawHunter surfacelaserfor the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Measured value

- surface, field

- Technology

- laser

- Applications

- for the aerospace industry

- Other characteristics

- automatic

Description

The FlawHunter is an integrated NDT inspection device, equipped with an advanced, high-resolution Laser Shearography sensor with a vacuum (partial) excitation system. It is ergonomic & easy-to-use and is equipped with a workflow-oriented, GUI-display and left/right-hand button control. Regardless of the application, the FlawHunter provides reliable and resolute measurement results for in-field (service) NDT and quality control (post-production) operations.

It can be used on any material & surface provided a stable vacuum can be generated within the vacuum seal (viewable inspection area).

The FlawHunter has a fully-integrated control electronics, as such there are no external connections to PCs, electronics, vacuum pump/s, and/or hoses.

The system only requires 1 connection to an external power source.

It weighs 9 kgs (20 lbs) and can inspect 320 mm x 230 mm (12.6 ‘‘ x 9 ‘‘) within a maximum of 10 seconds* (including*; placement, clamping & measurement), yielding an inspection rate of 0.44 m²/min (4.7 ft²/min)!

The vacuum pump typically requires 3-5 seconds to reach a steady vacuum level.

The FlawHunter can be equipped with either; a 3.2 MPx (standard) / 5 Mpx (optional), 12-bit, GigE camera with a (respective) maximum frame rate of 37 / 24 Hz. The internal sensor has a fully SW–controllable, automatic shearing piezo. Using the 4+4 Phase Shifting technique in conjunction with stable vacuum control via the integrated vacuum pump & controller, users can set the vacuum (pressure) level down to -11 kPa with a tolerance of +/- 0.05 kPa.

The result yields measurement images with the best definition and clarity with minimal noise.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Dantec Dynamics ‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.