- Production - Materials - Metrology

- Production machine

- 5-axis machining center

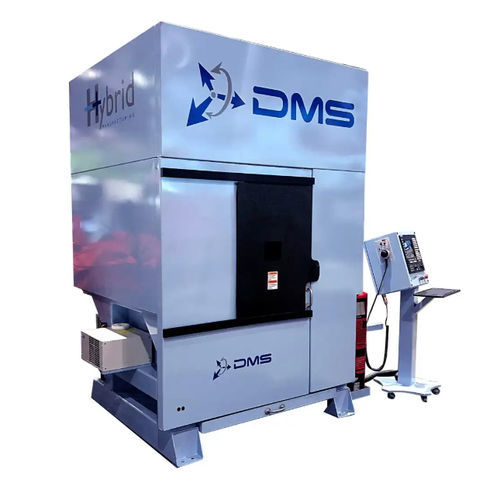

- DIVERSIFIED MACHINE SYSTEMS (DMS)

5-axis machining center Hybrid Herohorizontalfor aeronauticsCNC

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Applications

- for aeronautics

- Other characteristics

- CNC

Description

Our Hybrid Hero CNC is designed to be an entry-level machine for customers who are interested in our hybrid manufacturing processes. The machine has been designed to fit through a standard 74″x 81” double door, and does not require as much floor space to operate as our larger machines. It is equally suited for process development and research or production runs of small parts. The optional tilt rotate table adds 5-axis deposition and machining capabilities.

Base Features

Electrically isolated aluminum table with 3/8” threaded inserts on 6” centers

Tool height setter to automatically measure and store tool length in CNC

4 position automatic tool change rack

Fully enclosed work area

Specs

Feedstock: Configured for .047” (1.2mm) diameter commercially available solid wire.

Materials: Aluminum

Deposition Rate: up to 3 lbs/hr

Build volume: 24″ x 24″ x 24”

Spindle: HSD 12 hp / 9 kW Liquid cooled 24000 RPM

Machine Frame: Heavy duty steel fabricated

Machine dimensions: 113”W(door open) x 70”D x 112” H

Axis Motion: Precision ball screws and linear rail used all axes

Servo & Drive System: Fagor closed-loop brushless AC servo motors and servo amplifiers on all axes

Controller: Fagor 8065 Q7a

Catalogs

No catalogs are available for this product.

See all of DIVERSIFIED MACHINE SYSTEMS (DMS)‘s catalogsOther DIVERSIFIED MACHINE SYSTEMS (DMS) products

Hybrid Machines

Related Searches

- Machining machine

- Aeronautic machining center

- 5-axis machining center

- CNC machining center

- Horizontal machining center

- Vertical machining center

- Machining center for the aerospace industry

- 3-axis machining center

- Gantry machining center

- Machining center with swiveling spindle

- Router

- Aeronautic router

- CNC router

- Machining center with moving table

- Composite router

- Plastic router

- Laser machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.