- Products

- Catalogs

- News & Trends

- Exhibitions

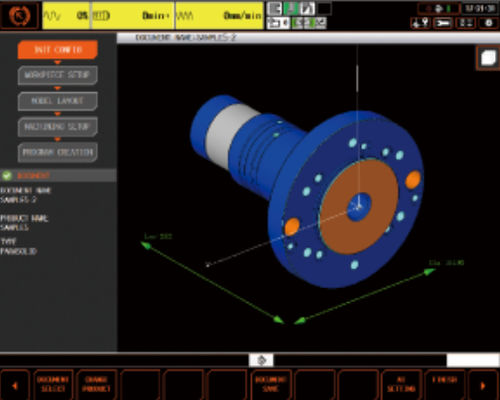

Programming software MAZATROL SMOOTH AiCADcuttingprocess

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- process, CAD, machining, programming, cutting

- Applications

- for aeronautics

- Type

- 3D

Description

Utilising cutting-edge digital technologies such as AI and digital twins, the system not only enhances operability but also achieves reductions in programming and setup time, shortens cycle time, and stabilises machining accuracy. Productivity can also be improved by enhancing automation systems. In addition, by linking with the digital twin software "MAZATROL DX", it becomes possible to perform digital setup in the office, which greatly improves the machine utilisation rate.

MAZATROL programs can be automatically generated from 3D models created with commercially available CAD software, greatly reducing programme man-hours. By learning machining know-how from programs created in the past, AI can generate optimal machining programs.

AI utilises machining expertise from accumulated programming experience. Based on the know-how, the machining process and processing conditions are automatically estimated and output as an optimal program.

1: [Without AI training]

Interrupted cutting will be required in the second process which will affect finished surface.

2: [With AI training]

Drilling is performed in the second process for a high-accuracy finished surface.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.