- Production - Materials - Metrology

- Surface treatment

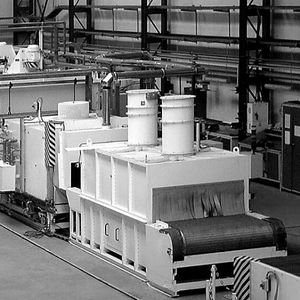

- Gas furnace

- SECO/WARWICK DO BRASIL LTDA

Gas furnace Vortex®conveyorfor the aerospace industryannealing

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Heat source

- gas

- Configuration

- conveyor

- Other characteristics

- for the aerospace industry, annealing

Description

SECO/WARWICK provides custom engineered aluminum annealing furnaces for coil and foil with capacities ranging from single coil furnaces to multi-zone furnaces with tight zone control. These units are used by aluminum manufacturers from around the world, i.e. in North & South America, Europe or Asia.

Using patented Vortex jet airflow technology, SECO/WARWICK’s Vortex® aluminum coils annealing system, combined with optional Bypass Cooler and SeCoil® control and simulation software, provides coils producers the ability to significantly reduce the overall cycle time of their furnaces, resulting in energy savings, increased productivity, and improved surface quality. The key to the system is an increased heat transfer coefficient achieved by high-speed air impinging on both sides of the coil. The idea is to transfer heat through the coil’s edges as opposed to only through the outside layer of the coil.

The challenge in aluminum coil annealing furnace is to optimize the process by shortening the cycle time to the greatest extent possible, while maintaining the desired metallurgical properties over the entire load. The components used in SECO/WARWICK’s aluminum coil annealing furnace succeed in providing both greater efficiency and better quality

The effective thermal conductivity in a strip coil is much lower in the radial direction than in the axial direction, therefore, the most effective way of heating the coil is through the edges of the coil layers. The difference between the thermal conductivity for the two directions is caused by the heat-insulating effect of the gas between the coil layers. Also, winding force of the coil plays crucial role in the process.

Catalogs

Aluminium Annealing Furnaces

4 Pages

Other SECO/WARWICK DO BRASIL LTDA products

Aluminum Furnaces

Related Searches

- Aeronautic drying oven

- Chamber furnace

- Electric drying oven

- Tunnel furnace

- Annealing furnace

- Combustion furnace

- Conveyor furnace

- Gas furnace

- Continuous furnace

- Furnace for the aerospace industry

- Heat treatment furnace

- Carburizing furnace

- Gas quenching furnace

- Pit furnace

- Brazing furnace

- Oil quenching furnace

- Vertical furnace

- Cabinet drying oven

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.