- Components - Spare Parts

- Hydraulic System

- Silicone hose

- TITEFLEX EUROPE SAS

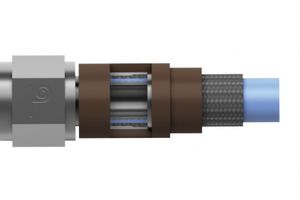

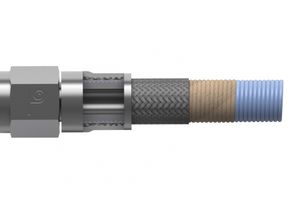

Silicone hose S145/245 Seriesfor aircraftreinforced

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Material

- silicone

- Other characteristics

- reinforced

Description

S145/245 Series: the premier and proven all-metallic aerospace hose, qualified to AS1424. S145 performs in extreme hot and cold, beyond the range of all thermoplastic hoses. It is used extensively on Space Vehicle and Launch Vehicle applications as well as hot sections of turbine engines where performance and reliability are critical. The hose consists of a convoluted innercore formed of CRES or Inconel® tubing, reinforced with a layer of 321 CRES wire braid. Operating pressures range from 2000 PSI (138 Bar) in small diameters to 800 PSI (55 Bar) in large diameters. S145 hose operates at temperatures up 1200°F without the need for firesleeve. Standard fittings are available in CRES or Inconel®. Hybrid assemblies combining flex hose with multi-bend tube are a Titeflex specialty and provide improved vibration dampening, ease of installation and maintenance over strictly rigid tubing. Titeflex can mold a proprietary silicone on S145 hose assemblies, encapsulating braid and innercore, for service in severe vibration applications. Where greater flexibility and tighter bend radius is required, in a less dynamic environment, Titeflex offers S245 hose. S245 is available in the same alloys as S145.

Catalogs

Related Searches

- Fittings

- Aircraft fittings

- Straight fittings

- Piping

- Fuel fittings

- Flexible piping

- Hydraulic fittings

- Not specified fittings

- Hose for aerospace applications

- Silicone hose

- Fuel hose

- PTFE flexible piping

- Construction flexible piping

- Hydraulic hose

- Braided hose

- Cooling hose

- Extruded flexible piping

- Fire hose

- Double hose

- Fire protection hose

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.