- Products

- Catalogs

- News & Trends

- Exhibitions

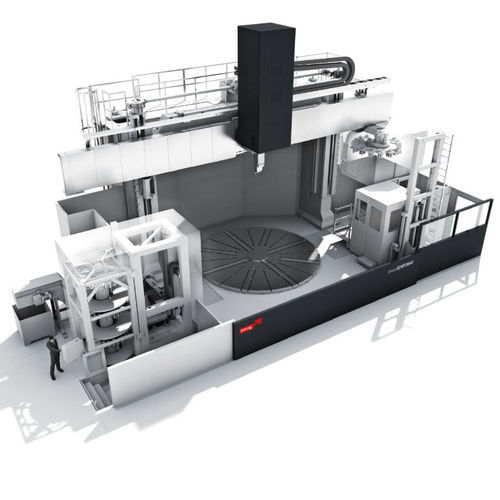

Vertical turning machine Dörries CONTUMAT VC 3500CNC3-axisfor the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Spindle orientation

- vertical

- Control type

- CNC

- Number of axes

- 3-axis

- Other characteristics

- for the aerospace industry

- Diameter

3,500 mm

(137.8 in)

Description

The Dörries CONTUMAT VC series, designed as a double column portal system, is ideal for larger swing diameters of 3,500 to 12,000 mm. The VC range combines all of the advantages of the VCE range with the ability to machine large scale components just as effectively. The positive construction properties of the smaller range are taken over here in correspondingly dimensioned main components. The range also provides high levels of flexibility by combining standard modules, providing the customer with a solution tailored to suit their individual needs.

The closed portal construction of the double column vertical lathe guarantees high intrinsic rigidity, while the proven cast construction ensures excellent damping and thermo-stability. Thanks to these characteristics customers obtain a lathe that provides high machining accuracy, with a long service life.

Palletizing

Automatic work piece changing equipment reduces set-up down time with increased manufacturing flexibility.

Tool magazines

Dörries lathes offer flexible tool handling systems. The multifunctional disc magazin offers up to 72 pockets, the chain type magazine up to 100 pockets and the column magazine with double gripper unit up to 210 pockets.

Head attachments

A wide variety of head attachments are available. These could be angular milling heads, universal-swivel heads, facing heads or grinding spindles.

Option boring, milling, grinding

The machine can be adapted with a boring and milling drive of 37 kW. Also grinding operations are optinal possible.

Main drive / C-axis drive

The main drive is powered by one or two electrically preloaded drive units with asynchronous motors. The power is max. 2 x 60 kW.

VIDEO

Related Searches

- Machining machine

- Aeronautic machining center

- 5-axis machining center

- CNC machining center

- Aeronautic milling machine

- Milling machine

- CNC milling machine

- Multi-axis milling machine

- Horizontal machining center

- Vertical machining center

- Machining center for the aerospace industry

- Aeronautic grinding machine

- Grinding machine

- Gantry machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Horizontal milling machine

- Turning center

- Aeronautic lathe

- CNC lathe

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.