- Production - Materials - Metrology

- Materials - Semi-finished products

- Epoxy resin prepreg

- Toray Advanced Composites

Epoxy resin prepreg BT250E-1thermosetting resinfor aeronautics

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Matrix

- epoxy resin, thermosetting resin

- Other characteristics

- for aeronautics

Description

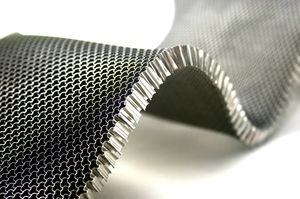

BT250E-1 resin system is a 121°C (250°F) cure epoxy prepreg system with excellent toughness and strength. It provides an outstanding surface finish under vacuum-bag/oven-cure only. The resin system, which is self-adhesive to honeycomb and foam core, is MIL-R-9300 qualified and makes a great choice for many applications in the low-to-medium-service temperature range.

Product benefits/features

MIL-R-9300 qualified

BT250E-1FR is the flame retardant version

Market segments

Energy

Aerostructures

Radome

Industrial

eVTOL / Urban Air Mobility

Details

Product category - Thermoset Prepreg

Processing - Out of Autoclave / Vacuum bag

Press forming

Autoclave

Resin type - Epoxy

Tg (Dry, onset) - 125 °C / 257 °F

Cure temperature (Optimal) - 121 °C / 249 °F

Cure temperature (Lowest) - 121 °C / 249 °F

Cure temperature (Highest) - 121 °C / 249 °F

Out life - 30 days

Catalogs

Toray BT250E-1

5 Pages

Related Searches

- Aeronautic composite

- Aeronautic honeycomb

- Composite

- Resin composite

- Composite for the aerospace industry

- Aeronautic prepreg

- Prepreg

- Resin prepreg

- Thermoplastic resin composite

- Carbon fiber composite

- Aluminum honeycomb

- Epoxy resin prepreg

- Composite resin

- Resin

- Fiberglass composite

- Epoxy resin

- Fire-resistant honeycomb

- Honeycomb for the aerospace industry

- Laminate composite

- Thermoplastic resin prepreg

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.