- Products

- Catalogs

- News & Trends

- Exhibitions

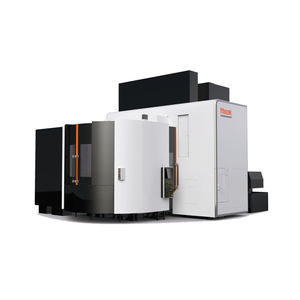

5-axis machining center INTEGREX e-670Hhorizontalverticalfor the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal, vertical

- Applications

- for the aerospace industry

- Other characteristics

- CNC, rotating table

- Rotational speed

10,000 rpm

(62,832 rad.min-1)- X travel

1,025 mm

(40.35 in)- Y travel

670 mm

(26.38 in)- Z travel

3,122 mm

(122.91 in)

Description

Multi-tasking machine capable of all operations from turning to milling of long and large workpieces

Large swing and Y-axis stroke for large workpieces

Wide variety of optional equipment for process integration and enhanced versatility

MAZATROL SmoothAi drives innovation for even higher productivity

Combining years of trust and technical expertise

Orthogonal design provides large operation area and high-accuracy machining

Powerful milling performance equivalent to that of machining centres. Highly rigid structure and wide variety of features for high-accuracy machining

Enhanced productivity through process integration

Reducing processes by one-eighth and lead times by one-fifth

The INTEGREX e-H series completes the entire process from raw material input to final machining with just one machine. Benefits include, a significant reduction in production lead time and high accuracy due to fewer setup processes; cost savings in terms of fixtures and equipment; reduced machine installation space and energy efficiency.

Powerful milling spindle for faster cycle times

Built-in motor spindle

A built-in motor spindle is adopted. Vibration is minimised during high acceleration/deceleration to ensure exceptional roundness and surface roughness.

Spindle temperature control

Temperature-controlled cooling oil is circulated around the spindle bearings and headstock to minimise thermal displacement of the spindle due to heat generation and maintain high machining accuracy.

VIDEO

Related Searches

- Mazak machining center

- Mazak aeronautic machining center

- Mazak 5-axis machining center

- Mazak CNC machining center

- Mazak horizontal machining center

- Mazak vertical machining center

- Mazak machining center for the aerospace industry

- Mazak 3-axis machining center

- Gantry machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Turning center

- Aeronautic lathe

- CNC lathe

- Machining center with moving table

- Lathe for the aerospace industry

- Vertical turning center

- Horizontal lathe

- Rotating table machining center

- Double-column machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.