- Products

- Catalogs

- News & Trends

- Exhibitions

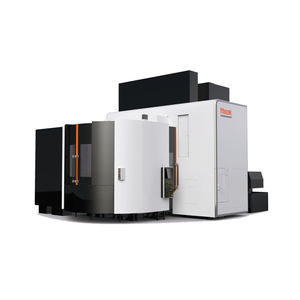

5-axis machining center INTEGREX e-RAMTEC V/12verticalfor the aerospace industryCNC

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Applications

- for the aerospace industry

- Other characteristics

- CNC

- Rotational speed

10,000 rpm

(62,832 rad.min-1)- X travel

3,055 mm

(120.28 in)- Y travel

1,700 mm

(66.93 in)- Z travel

1,800 mm

(70.87 in)

Description

Simultaneous 5-axis vertical multi-tasking machines with Ram spindle

Long X-axis and Y-axis strokes for high-accuracy machining of large parts

Ram spindle for deep inner diameter boring and milling

High-accuracy machining with double column construction

Double column construction suitable for top face machining of large parts

By taking advantage of the double column construction and the long X-axis stroke beyond the milling spindle, top face milling can be performed with only linear X- and Y-axis positioning, resulting in stable machining accuracy and higher productivity.

Ram spindle mounted on 5-axis controlled vertical multi-tasking machines

Ram spindle

The ram spindle with a vertical stroke of 900 mm, mounted next to the milling spindle, performs deep inner diameter turning and milling that cannot be machined even with long tools, thus achieving further process integration.

Automatic ram spindle tool changer

A dedicated tool magazine can hold 40 turning and milling tools. The machine can handle a wide variety of machining and change to spare tools during long-term machining.

Milling spindle

Built-in motor milling spindle is both compact and high power. In addition to the 10,000 min-1 standard spindle for various materials, there is a 5,000 min-1 optional spindle suitable for high-torque machining of difficult-to-machine materials and a 15,000 min-1 optional spindle that enables high-speed machining.

The B-axis (travel: 150°) is indexed and positioned with high precision over the long term using a roller gear cam which eliminates backlash.

Related Searches

- Mazak machining center

- Mazak aeronautic machining center

- Mazak 5-axis machining center

- Mazak CNC machining center

- Mazak horizontal machining center

- Mazak vertical machining center

- Mazak machining center for the aerospace industry

- Mazak 3-axis machining center

- Gantry machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Turning center

- Aeronautic lathe

- CNC lathe

- Machining center with moving table

- Lathe for the aerospace industry

- Vertical turning center

- Horizontal lathe

- Rotating table machining center

- Double-column machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.