- Products

- Catalogs

- News & Trends

- Exhibitions

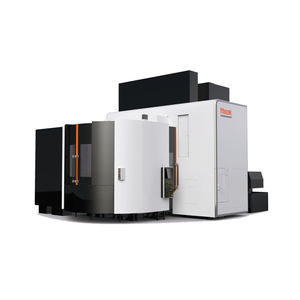

5-axis machining center INTEGREX e-1250V/8horizontalfor aeronauticsCNC

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Applications

- for aeronautics

- Other characteristics

- CNC, rotating table, double-column

- Rotational speed

10,000 rpm

(62,832 rad.min-1)- X travel

1,875 mm

(73.82 in)- Y travel

1,250 mm

(49.21 in)- Z travel

1,345 mm

(52.95 in)

Description

Simultaneous 5-axis double-column machining centre suitable for large workpieces

Double-column machining centre performs multi-surface machining, free-form surface machining by 5-axis control and turning for higher productivity

Highly rigid structure for stable high-accuracy machining

Table enhanced with direct drive motor for high-torque and high-speed positioning

Automation systems to meet your production requirements

MAZATROL SmoothAi drives innovation for even higher productivity

Wide range milling with double column construction

Double column construction suitable for top face machining of large workpieces

By taking advantage of the double column construction and the long X-axis stroke beyond the milling spindle, top face milling can be performed with only linear X- and Y-axis positioning, resulting in stable machining accuracy and higher productivity.

High-power milling spindle and direct-drive table for turning

Enhanced milling performance for high-productivity

Three milling spindles are capable of machining a wide range of materials from steel to non-ferrous materials. All of them achieve compact size and high-power by adopting a built-in motor.

High-torque, high-speed table

(turning & C-axis)

A direct drive motor that can output large torque in a compact volume is used to achieve both the high torque required for turning large workpieces and the high response that enables agile positioning.

Compatible models: INTEGREX e-1250V/8, e-1250V/8S, e-1600V/10, e-1600V/10S

Related Searches

- Mazak machining center

- Mazak aeronautic machining center

- Mazak 5-axis machining center

- Mazak CNC machining center

- Mazak horizontal machining center

- Mazak vertical machining center

- Mazak machining center for the aerospace industry

- Mazak 3-axis machining center

- Gantry machining center

- Machining center with swiveling spindle

- 4-axis machining center

- Turning center

- Aeronautic lathe

- CNC lathe

- Machining center with moving table

- Lathe for the aerospace industry

- Vertical turning center

- Horizontal lathe

- Rotating table machining center

- Double-column machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.