STARRAG 5-axis machining centers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

X travel: 450 mm

Y travel: 670 mm

Z travel: 665 mm

... optimum chip fall. Axis arrangement Three linear and two rotary axes permit 5-sided machining as well as 5-axis simultaneous interpolation. Overhead machining The ...

GROB-WERKE GmbH & Co. KG

Rotational speed: 18,000 rpm - 24,000 rpm

X travel: 4,800, 6,000, 3,600 mm

Y travel: 2,600, 1,800 mm

The perfect closed cell CNC 5-axis machining center. Multiax has developed a 5-axis machining center for fast and ...

MULTIAX INTERNATIONAL CNC SRL

Rotational speed: 18,000 rpm - 24,000 rpm

X travel: 3,100, 1,800, 2,600 mm

Y travel: 3,000, 1,500 mm

The most intelligent and compact 5-axis NC machining center, with monolithic closed-cell structure, designed with moving bridge, conceived for high-level performance. ...

MULTIAX INTERNATIONAL CNC SRL

Rotational speed: 18,000 rpm - 24,000 rpm

X travel: 2,600 mm - 5,000 mm

Y travel: 1,500 mm

Compact, yet highly powerful, precise and versatile 5-axis CNC milling and machining center mounted on a monobloc basement. Its welded and reinforced, ...

MULTIAX INTERNATIONAL CNC SRL

Rotational speed: 5,000 rpm

X travel: 370 mm

Y travel: 200 mm

... for high-accuracy machining Long Y-axis stroke A generous Y-axis stroke of ±100 mm is achieved by using the proven orthogonal Y-axis structure. This provides a wide ...

MAZAK

Rotational speed: 15,000 rpm

X travel: 762 mm

Y travel: 460 mm

... with pre-loaded apps Massive Trunnion- Superior accuracy and machining capabilities Pre-Tension Ballscrews- Uncompromising precision Our new, next-generation, 5-axis vertical machining ...

OKUMA CORPORATION

... handling tools weighing 4 kg, the new advanced version is the fastest and strongest vertical machining centre on the market. With the shortest cycle times on most machining operations, all ROBODRILL machines ...

Rotational speed: 8,100 rpm

X travel: 762 mm

Y travel: 406 mm

The VF-2TR is a versatile 5-axis machining center based on the popular VF-2 VMC platform. It provides full simultaneous 5-axis motion, or can position ...

HAAS AUTOMATION

Rotational speed: 30,000 rpm

X travel: 400 mm

Y travel: 200 mm

... integral machining concept for pre and postprocessing in a clamping position Turbine blade machining center The LX series was specifically designed for the high-precision, efficient ...

STARRAG AG

X travel: 710, 900 mm

Y travel: 750, 950 mm

Z travel: 710, 930 mm

... the production of your workpieces. Key facts 5-axis machining centres HF at a glance horizontal 5-axis machining centres with pallet changer or table loading universal ...

Heller Machine Tools Ltd

Rotational speed: 30,000 rpm

X travel: 4,800, 5,800, 7,800, 8,800, 10,800 mm

Y travel: 2,000, 2,500 mm

... for high-speed milling of aluminum structural parts. The proven bavius pallet changer keeps non-productive time to a minimum. High-speed milling When producing large aluminum structural parts the ...

BAVIUS TECHNOLOGIE GMBH

Rotational speed: 24,000, 36,000 rpm

X travel: 2,100 mm

Y travel: 1,480 mm

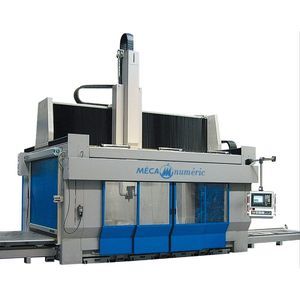

... molds or 5-axis machining of thermoformed, rotational molded parts ... TECHNOLOGIES Transmission by ball screw on the 4 Cartesian axes (X1, X2, Y, Z) 2 rotary axes (C: +/- 200 ...

Breton Hawx is the vertical gantry monobloc, 5 axis, milling centre for machining light alloys, resin, or composite materials The HAWX E2 foresees a pre-assebled starting ...

Breton SpA - Advanced Technologies

Rotational speed: 15,000 rpm

The CMS vm 30k vertical CNC machining center is the perfect solution for milling complex three-dimensional parts requiring precision, repeatability and an excellent surface finish with ...

CMS SPA

Rotational speed: 10,000 rpm - 30,000 rpm

X travel: 800 mm

Y travel: 800 mm

... x 500 500 x 500 Ø 630 Option 2 2 - mm 500 x 630 500 x 630 - Rotary Table (B-Axis) - Max. Rotation Speed - min-1 - 100 - 100 - 100 / 1.200 5th Axis (A-Axis) ...

Machining Centers Manufacturing SPA

Rotational speed: 15,000, 18,000, 25,000, 30,000, 42,000 rpm

X travel: 450 mm

Y travel: 600 mm

... and the highest possible machine dynamics:: The flexible C 22 machining centre is ideal for machining high-value parts with excellent accuracy and small tolerances. As with most Hermle machining ...

MASCHINENFABRIK BERTHOLD HERMLE AG

... traveling column design of the FZ 12 S five axis, you can manufacture workpieces with high surface quality in one clamping position. Both the single spindle variant and the DZ 12 S five axis carry out ...

CHIRON-WERKE GMBH & CO.KG

X travel: 600 mm

Y travel: 240 mm

Z travel: 395 mm

Make use of your competitive advantages! The 5 axis machining center HSTM with horizontal component orientation is particularly suitable for the machining ...

HAMUEL MASCHINENBAU GMBH & CO. KG

Rotational speed: 15,000 rpm - 40,000 rpm

X travel: 3,000 mm

Y travel: 2,600 mm

DIAMOND LINEAR 30 is a gantry style machining centre with 3 or 5 axis for high speed moulds/dies machining as well as aerospace jobs. It features a monobloc structure ...

Parpas SpA

Rotational speed: 15 rpm - 6,000 rpm

X travel: 900 mm

Y travel: 900 mm

... the No. 1 delivery record of trunnion type horizontal 5 axes machining centers. ●A wide variety of palette sizes from 500 to 1000 are available. ●The center ...

MITSUI SEIKI KOGYO CO., LTD

... core and subsequently cured. The fibres are aligned at an angle of between 0° and nearly 90° in relation to the longitudinal axis of the component. The winding machine can be controlled via five axes simultaneously and ...

Precision drilling is a critical requirement for aerospace operations. Whether drilling DA holes or precision fastener holes, in composite skins or multiple material assemblies, PaR provides optimal drilling solutions. From wing spars ...

Rotational speed: 40,000, 28,000 rpm

X travel: 340 mm

Y travel: 100 mm

... excellent rigidity and anti-vibration properties, ensuring high-precision machining Positioning accuracy of 5μm, repeatability of 3μm High-precision A/B Axis, hollow stainless steel ...

Conprofe Technology Group Co., Ltd.

Rotational speed: 30,000 rpm

X travel: 6,000 mm

Y travel: 2,300 mm

... automated 5 Axis Profile Beam Machining Center with integral “Smart Fixturing™”system. Designed for fast, highly automated performance in “one off” demand-driven manufacturing environments ...

BERTSCHE MACHINE TOOLS

X travel: 60 in

Y travel: 144 in

Z travel: 18 in

This 5 -Axis Large Format Gantry CNC Machine is a continuous-use, heavy duty, large scale machine that can be used to process a wide range of applications from light materials such as wood and foam to ...

DIVERSIFIED MACHINE SYSTEMS (DMS)

Rotational speed: 0 rpm - 10,000 rpm

The TARUS TBM is a Moving Gantry Machining Center. Intended uses are Finish Milling of Steel / Invar Layup Tools, Milling and Drilling of Aluminum and Epoxy Aerospace ...

Tarus

Rotational speed: 300, 350, 400, 6,000 rpm

... vertically, during both milling and turning operations. While retaining all the characteristics of Pietro Carnaghi vertical lathes, Flexturn is created to meet the modern requirements of: Compactness (compared to standard ...

Your suggestions for improvement:

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how AeroExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining