STARRAG horizontal machining centers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

X travel: 450 mm

Y travel: 670 mm

Z travel: 665 mm

... smallest universal machining center in the unique G-module concept of GROB and enables customers from various industries to machine with the highest precision. With direct and absolute position encoders ...

GROB-WERKE GmbH & Co. KG

Rotational speed: 30,000 rpm

X travel: 400 mm

Y travel: 200 mm

... integral machining concept for pre and postprocessing in a clamping position Turbine blade machining center The LX series was specifically designed for the high-precision, efficient ...

STARRAG AG

Rotational speed: 10,000 rpm

X travel: 1,025 mm

Y travel: 670 mm

... provides large operation area and high-accuracy machining Powerful milling performance equivalent to that of machining centres. Highly rigid structure and wide variety of features ...

MAZAK

Rotational speed: 50 rpm - 15,000 rpm

X travel: 760 mm

Y travel: 760 mm

... need Faster Positioning & Table Indexing - Reduced Cycle Time Our MB-5000HII is a high-speed, thermally-stable horizontal machining center that offers quick acceleration, short tool ...

OKUMA CORPORATION

Rotational speed: 3,500 rpm - 5,000 rpm

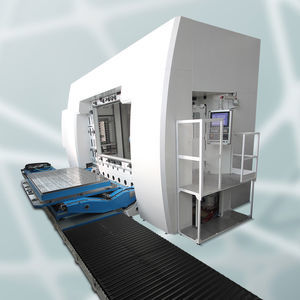

X travel: 2,000 mm - 4,600 mm

Y travel: 1,700 mm - 3,500 mm

PAMA Speedmat HP machining centers are able to combine high dynamics and rigidity and optimum precision to satisfy also the most difficult applications when machining small/and medium-sized ...

PAMA SPA

X travel: 6,500 mm

Y travel: 3,000 mm

Z travel: 500 mm

The STAXX COMPACT is robust standalone 16-lane fiber placement machine designed for high volume industrial production. The system is ideally suited for the mass production of small composite parts. It achieves high workpiece quality while ...

Broetje-Automation

X travel: 630 mm - 2,400 mm

Y travel: 630 mm - 1,600 mm

Z travel: 630 mm - 1,600 mm

... you robust processes – even at their limits, seven days a week in 3-shift operations. 4-axis machining centres H at a glance horizontal 4-axis machining centres with pallet changer ...

Heller Machine Tools Ltd

Rotational speed: 30,000 rpm

X travel: 4,800, 5,800, 7,800, 8,800, 10,800 mm

Y travel: 2,000, 2,500 mm

... for high-speed milling of aluminum structural parts. The proven bavius pallet changer keeps non-productive time to a minimum. High-speed milling When producing large aluminum structural parts the ...

BAVIUS TECHNOLOGIE GMBH

Rotational speed: 24,000, 40,000 rpm

X travel: 2,600 mm

Y travel: 1,500 mm

5-axis high speed CNC machining center with monobloc structure Its compact design easily fits into any production environment, while still benefitting from the large working envelope. The monobloc ...

CMS SPA

Rotational speed: 10,000 rpm - 30,000 rpm

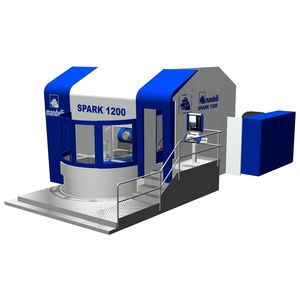

X travel: 800 mm

Y travel: 800 mm

Pallet - Option 1 - mm 500 x 500 500 x 500 Ø 630 Option 2 2 - mm 500 x 630 500 x 630 - Rotary Table (B-Axis) - Max. Rotation Speed - min-1 - 100 - 100 - 100 / 1.200 5th Axis (A-Axis) - Type - - - - Tilting Table - Tilting ...

Machining Centers Manufacturing SPA

Rotational speed: 15,000, 18,000, 25,000, 30,000, 42,000 rpm

X travel: 450 mm

Y travel: 600 mm

... and the highest possible machine dynamics:: The flexible C 22 machining centre is ideal for machining high-value parts with excellent accuracy and small tolerances. As with most Hermle machining ...

MASCHINENFABRIK BERTHOLD HERMLE AG

X travel: 600 mm

Y travel: 240 mm

Z travel: 395 mm

Make use of your competitive advantages! The 5 axis machining center HSTM with horizontal component orientation is particularly suitable for the machining of turbine ...

HAMUEL MASCHINENBAU GMBH & CO. KG

X travel: 750 mm

Y travel: 800 mm

Z travel: 850 mm

... X, Y, and Z) to realize the feed rate of 48 m/min and acceleration of 0.5 G, which is the highest in this class. ●Center trough eliminates troubles caused by cutting chips. ●In addition, HW55A is equipped ...

MITSUI SEIKI KOGYO CO., LTD

The winding machine is a special facility which is used by INVENT to produce precedential rotational components, such as pressure tanks or cross braces from fibre composite materials. For this, fibre bundles, so-called rovings, are soaked ...

Z travel: 36, 48 in

The DMS 5 -Axis Moving Table CNC machine features a moving table design with moving single or twin tables and single or multiple spindle options. This line of router is available in a range of sizes and styles to accommodate various production ...

DIVERSIFIED MACHINE SYSTEMS (DMS)

This open configuration Horizontal Arm 5 Axis Mill is ideal for milling large Aerospace Tooling that would otherwiser require a very wide and very tall gantry in order for the tooling base to fit inside ...

Rotational speed: 3,000 rpm

Y travel: 2,000 mm - 4,000 mm

... with additional attachment heads. The flexibility of the center can offer a wide range of solutions, from the standalone machine to a full FMS system. A complete range of advanced milling attachment ...

INNSE-BERARDI SPA

Rotational speed: 500 rpm - 30,000 rpm

X travel: 3,200 mm

Y travel: 2,000 mm

Monnalisa is the innovative horizontal 5 axis milling centre specifically developed for machining monolithic, structural, large dimension aluminum parts, particularly suitable for aerospace ...

COMI S.p.A.

X travel: 4,000 mm - 8,500 mm

Y travel: 2,000 mm - 4,000 mm

Z travel: 1,200 mm - 1,500 mm

... , high-speed horizontal milling centres, featuring: • high dynamic performance in terms of accuracy and stiffness on large axes strokes • reduced operating costs • simplified maintenance • ...

... column Drilling Machines are built in various sizes to meet customer requirements and specifications and can be built for milling purposes too. The TORRESDRILL, can be integrated with different solutions to fulfil ...

... transpallet system housing up to 9 pallet tables or single, double or three-level multipallet storage FMS. MACHINING CENTER / HORIZONTAL PROFILER You can find all the details and ...

MANDELLI SISTEMI SPA

X travel: 3 m - 4 m

Y travel: 2 m - 3 m

Z travel: 1 m

... accuracy on the tool bit, drastically abating vibrations and obtaining high quality work surfaces in the milling phase. SKY is a machining center with screw handling, equipped with optical ...

BELOTTI SPA

X travel: 4,100 mm

Y travel: 1,600 mm

Z travel: 650 mm

... Zimmermann milling heads, the FZH400 ensures an extremely effi cient milling process during the machining of aluminum and composites – a basic prerequisite for economic workpiece machining. The ...

Rotational speed: 1 rpm - 36,000 rpm

X travel: 200 mm

Y travel: 350 mm

| Loading/unloading in parallel to machining time | Maximum productivity through multi-spindle capability | Highest productivity in minimum space QUALITY | High machine rigidity due to patented monoblock design EASE ...

SCHWAEBISCHE WERKZEUGMASCHINEN GMBH

CMF Groupe design and realize special machining machines. We customized our machining machines according to the customers’ needs. The Company’s strategy relies on 3 main axes : highly ...

CMF CONCEPTION MACHINES FAVEYRIAL

Your suggestions for improvement:

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how AeroExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining